In March of this year, after 2 separate crashes killed a combined 346 people, the Boeing 737 Max was grounded. Details from the 2 incidents showed that they were both caused by the same issue…the MCAS, or maneuvering characteristics augmentation system malfunctioning. The MCAS is designed to keep the aircraft from stalling, by pushing the nose of the plane down. As you might imagine, it’s not a good thing when it malfunctions and begins pushing the nose of the plane down during normal flight. Since it can’t be physically overpowered by the pilots, and most weren’t trained to override it, it was a tragedy looking for a place to happen and, sadly, it did…twice.

Boeing 737 Max: Why Quality Control Matters – Errors of Omission

On November 15th, 2016, Mark Forkner, a technical pilot for Boeing, reported that the MCAS flight system on the Boeing 737 Max was “running rampant” while he was undergoing flight testing in a flight simulator. This was roughly 2 years before the Boeing 737 Max was certified, but for some reason…and I’ll leave the speculation out…the FAA was not notified of the problems. And, according to this article from CBC News, the MCAS was only mentioned once in the Boeing 737 Max manual, in the abbreviations section. The article quoted Judson Rollins, a New Zealand based aviation consultant as saying; “I think the fairly obvious conclusion is that a broader explanation of MCAS was included in an earlier edition of the manual, and somewhere along the way it ended up on the cutting room floor.”

He also added that he believes it was likely to cut “to prevent the MCAS from having to be included in 737 Max transition training, which in turn would save 737 Max operators training costs.” Raymond Hall, for former Air Canada pilot was quoted in the article as well, and his words cut to the heart of the matter; “The system is critical to the safety of the flight. And pilots ought to have known that it was there, ought to have been able to recognize it when it was implemented, and ought to have been able to respond effectively.”

Boeing 737 Max: Why Quality Control Matters – It’s Not Just Boeing

In July of this year, CBS News posted a story about the first canceled order for the Boeing 737 Max. Flyadeal had had earlier planned to buy 50 Boeing 737 Max jets for 5.9 billion dollars, but reversed that decision and purchased Airbus planes instead. That was good news for Airbus, but it certainly didn’t help the airlines who had already purchased Boeing 737 Max’s for their fleets and had to ground them. As CNBC reported on October 13th, the grounding (which has gone on for almost 9 months now) are beginning to pile up huge costs for those airlines.

In the third quarter of this year alone, American Airlines has had to cancel 9,475 flights due to the groundings at a cost of roughly 140 million dollars. They expect to cancel more than 14,000 flights in the 4th quarter and early January. They have 24 Boeing 737 Max jets in their fleet and have another 76 on order. Unfortunately, American Airlines is only one of 37 airlines who have taken delivery of the Boeing 737 Max jets, so the costs to the industry are far more than just those American has suffered. Boeing took a 4.9 Billion dollar charge in the second quarter to cover compensation costs to airlines affected by the groundings…and there’s no sign the 737 Max will be cleared to fly before the end of this year, so those costs just keep going up.

Boeing 737 Max: Why Quality Control Matters – The Supply Chain

With hundreds of suppliers producing thousands of parts for the Boeing 737 Max, the ripple effect of the grounding, and subsequent slowdown in manufacturing of the jet is being felt by all. As detailed in a June 13th story in the Wall Street Journal, Robert Wall and Andrew Tangel lay out the tough decisions that are having to be made by suppliers to Boeing for the 737 Max. Though Boeing has slowed it’s production rate of 737 Max planes from 52 per month to 42 per month, it’s suppliers have not slowed their production rates as of yet. Part of the reason is that they need the extra time to catch up, because the demand for parts prior to the groundings, from the aircraft industry as a whole, was huge. Boeing and Airbus’s voracious need for parts had strained the supply lines, causing shortages of things like engines and seats.

Now they have some breathing room, but there’s just one problem. They’re making things like seats, engines, and fuselages faster than they can be consumed. That means they have to add them to inventory, and that they aren’t getting paid for them until they get delivered. Spirit AeroSystems in Wichita, which makes the fuselage for the Boeing 737 Max is still producing 52 of them a month. They are storing them outside their facility, while they are storing the wing flaps and pylons used to mount the engines indoors. It’s not hard to figure out that, if you’re building 52 plane fuselages a month, and only moving 42 off your property, it won’t be long till you run out of storage space. Oh yeah, and you only get paid for the 42 you delivered, not the 52 you made. And that brings us to the big picture…the economy.

Boeing 737 Max: Why Quality Control Matters – The Economy

Mathew Klein opined in his piece in Barron’s in late October about the sheer size of the problem we’re grappling with over the grounding of the Boeing 737 Max, and how it’s literally affecting the overall economy of the United States. He notes that the U.S. is the world’s largest economy and that we produce a variety of goods and services that total 21 Trillion dollars in value every year.

He poses the question of how one company, in what he calls “this mammoth economic ecosystem” could cause even a ripple. But, as he notes, Boeing has. Boeing’s own website shows that they have 4,592 unfulfilled orders for the Boeing 737 Max. So, unless or until the 737 Max is cleared to fly again, that’s a lot of economic value setting idle. Since the planes can’t fly, none are being delivered. With an average cost of 188 Million dollars each, the backlog of 737 Max’s is valued at over a half a trillion dollars! It’s not hard to see how that might move the economic needle.

Boeing 737 Max: Why Quality Control Matters – Manufacturing

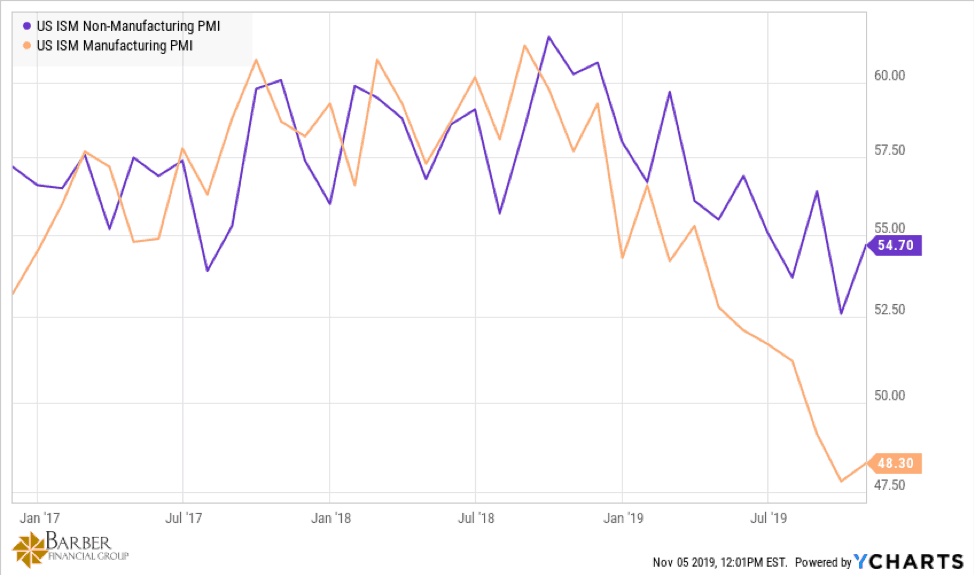

According to the census bureau, new orders of civilian aircraft and parts were 54% lower for the April to June period than in the preceding 12 months. Not surprising when you consider that Boeing will not be able to deliver the 468 737 Max jets it would have produced had the grounding not happened. That shortfall is showing up in charts everywhere. Here’s one:

Source: YCharts.com

This chart shows the ISM Manufacturing Index versus the Non-Manufacturing (Services) Index. Any reading above 50 indicates expansion and any reading below 50 indicates contraction. Note that the 2 were tracking pretty well in unison, nicely in expansion territory for the last 3 years, until the grounding of the Boeing 737 Max. At that point, the Manufacturing index took a dive, and though it ticked up in October, it’s been in contraction now for 3 full months. It’s worth noting that the 40 plus day GM Strike was a contributor to the contraction as well, and its end may have something to do with the uptick.

Additionally, the concern over the trade tensions with China may have contributed to the contraction. There is no denying though, that the main mover of the decline in the ISM Manufacturing index was triggered by, and largely driven by, the grounding of the Boeing 737 Max.

In Conclusion

With so many people, so many industries, and so much of the economy being affected by questionable decisions, made by people in one company, about taking one product to market, I hope that everyone, in every business no matter how large or small will take a renewed look at their quality control processes and procedures. Because just like with the Boeing 737 Max, quality control really does matter.

As always, if you have questions about how recent economic events can impact your retirement; give us a call at 913-393-1000 or schedule a complimentary consultation below.

Schedule a Complimentary Consultation

Select the office you would like to meet with. We can meet in-person, by virtual meeting, or by phone. Then it’s just two simple steps to schedule a time for your Complimentary Consultation.

Lenexa Office Lee’s Summit Office North Kansas City Office

Investment advisory services offered through Modern Wealth Management, Inc., an SEC Registered Investment Adviser.

The views expressed represent the opinion of Modern Wealth Management an SEC Registered Investment Advisor. Information provided is for illustrative purposes only and does not constitute investment, tax, or legal advice. Modern Wealth Management does not accept any liability for the use of the information discussed. Consult with a qualified financial, legal, or tax professional prior to taking any action.